|

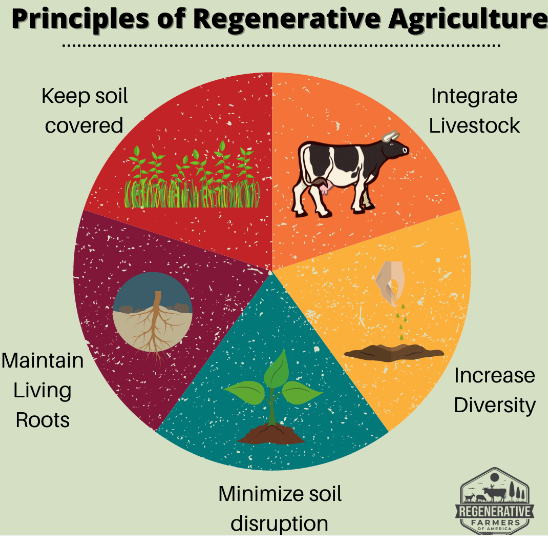

Regenerative agriculture is a buzzword you might have heard lately. But what does it mean? Check out this video from Regenerative Farmers of America to learn more: Regenerative agriculture aims to improve sustainability for land, water, wildlife, people, and rural communities & economies. While there are certainly challenges to implementing regenerative practices within current systems on a global scale, many farmers across America and beyond have begun to see the benefits of these practices. In a nutshell, regenerative practices include:

Additionally, the principle of knowing your farm's context is often included, as each piece of land is different based on things like soils, topography, and climate. Practices that work well on one farm wont' always be best on another farm. Golden Hills will be working with local farmers in the coming years to incorporate practices that build soil health and provide environmental benefits, as well as more nutritious food and help rural communities.

Stay tuned and learn more at goldenhillsrcd.org/regenag

0 Comments

You may remember Danelle Myer from our earlier post about One Farm Market in Logan. We visited Danelle again, this time at the farm during the peak of the growing season. Danelle grew up on a conventional rowcrop farm in the rolling hills of southwest Iowa, near Logan in Harrison County. She moved away for college, where she studied public relations, then worked in PR and marketing for more than 15 years. During that time she liked gardening and cooking, but enjoyed her work and wasn’t looking for a career change. Danelle became interested in healthy eating and learned about the benefits of organic agriculture and food. When she realized the opportunity and incredible privilege she had with access to family land, Danelle decided she wanted to grow food for her hometown community. She was accepted into an apprenticeship program at University of California-Santa Cruz Center for Agriculture & Sustainable Food Systems, where she learned about sustainable and healthy food production. She then moved back to Logan and started One Farm. Currently One Farm is growing several of types of potatoes. cabbage, peppers, green beans, tomatoes, chard, parsley, beets, rhubarb, cukes, summer squash, and more. One Farm Market is the primary sales outlet, and the store recently moved to a larger space. One farm also has Thanksgiving Bounty Boxes that sell out every year--order yours here!

Heath and Katie Hoppes started Hidden Hollow Farm in 2015 with a hay, small grains, and corn rotation on about 80 acres in the Loess Hills of Pottawattamie County. The Hoppes family’s goal was to grow more of their own food, know how it was raised, and to become more self-sufficient. Their crops have been Certified Organic since 2018. This year they had about 50 acres of hay, which is used to feed their cattle during the winter months. In addition to crops, they started raising broiler chickens in 2018, then later added pigs, and finally Aberdeen cattle. They raise 10-15 hogs per year, and currently have 30 head of cattle. The cattle are primarily grass-fed but do eat some spent grains from Full Fledged Brewing in Council Bluffs. They are rotated on several paddocks of grass including both native prairie species and brome. The hogs and cattle are processed at KB Meats in Blair, NE. Hidden Hollow typically has 2-3 batches of broilers per year, and a batch of turkeys each fall that are ready just in time for Thanksgiving. Customers can also order online or contact the farm to pick up on the farm. They also sell at the Council Bluffs Farmers Market. While they encourage you to try their products, they also want to promote local foods more broadly and support other local farmers.

Learn more by visiting their website, Facebook page, and Instagram. Emily & Nathan Paulsen, started Brun Ko Farm in 2015, with a milk cow and a few bottle calves. Since then, they have relocated twice, and finally landed at their current location east of Elk Horn in 2017. They started with 6 acres and have scaled up to 15. Unfortunately due to regulations and restrictions, they realized a dairy farm would be extremely difficult and have pivoted their focus to meat and vegetables. Brun Ko means Brown Cow in Danish, a nod to the area’s Danish heritage. Emily & Nathan currently have a small herd of Aberdeen angus, along with pigs, laying hens, and broiler chickens. They also graze sheep for Harrisdale Homestead periodically through the summer. Their beef, pork and lamb is processed at Anita and Minden lockers, while their chickens are processed at Duncan Poultry. During late winter/early spring, Emily starts her seeds in a heated greenhouse but for fall crops, she uses a carport with shade cloth. Emily uses soil blocks as an alternative to plastic containers. Brun Ko prefers to use Beautiful Land soil c3 when making soil blocks. In addition to starting vegetable transplants, Emily also grows flowers for companion planting to attract beneficial insects to the vegetable fields. Brun Ko grows tomatoes, lettuce, carrots, cabbage, onions, beans, peppers, and herbs on about ¼ acre. This year they are growing sweet potatoes for the first time. They have also planted asparagus, fruit trees, and berries, which take a few years to produce at scale. In addition to their meat and eggs, Brun Ko Farm is probably best known for their lettuce and spring mix. They currently have about 3 cow/calf pairs, 100 laying hens, 200 broilers twice a year, and 4 pigs. Meat can be purchased in wholes and halves and as individual cuts. Emily & Nathan are finishing up work on a new pack shed that will improve their ability to wash and prepare crops from the field for market. This will also help them scale up vegetable production. You can find Brun Ko’s products at Produce in the Park on Thursdays from 4:30 to 6:30 at the Atlantic City Park. They also sell through Farmtable Delivery. The Kringle Man in Elk Horn sells their produce, and One Farm Market in Logan sells their meat.

Visit their website and Facebook page to learn more about Brun Ko Farm. Matt & Jocelyn Vermeersch operate Mud Ridge Ranch on a hilltop overlooking Mud Hollow north of Council Bluffs. Matt didn’t grow up farming but was raised in a rural western Iowa community and was always interested in agriculture. After living in several different states, a job brought him back to this area. They bought a house with about 5 acres in 2019, and their first livestock was a small goat herd. After goats, they got into Scottish Highland cattle, then sheep. They currently have 30 highland cattle. They raise registered cows with the American Highland Cattle Association and the Heartland Highland Cattle Association as well as a handful of unregistered highlands. They also raise chickens and ducks. Eggs are primarily sold locally by word of mouth, so contact the farm directly if you would like to buy their eggs. They are considering raising meat birds in the future. Last year, they started directly selling meat. The meat is processed in Guthrie Center at a state certified facility that opened in 2023. Like the eggs, the best way to buy their meat products is to contact them directly. In 2022 they became an affiliate of Goats on the Go. Private landowners and conservation agencies are increasingly using goats for brush management and invasive species removal. They have two goat herds totaling around 200 animals. They operate a large herd of 150 goats and sheep for larger projects that are bigger than 10 acres. The smaller herd of about 40 goats tackles smaller projects and still has openings yet this year, so contact them if you’re interested. In addition to their own land, Mud Ridge Ranch lease more than 100 acres from nearby neighbors. This year, for the first time, they are hiring an intern to help manage the farm. Matt recommends people look into Goats on the Go, and encourages beginning farmers to get involved with Practical Farmers of Iowa to learn more about farming, and to network with other farmers. To buy their meat or eggs, contact them directly through their website, Facebook, or by email or phone (712-292-1230).

Aqua Archer Farms is a small aquaponics farm in Missouri Valley. While working for UPS, owner Chris Archer delivered an aquaponics system and was intrigued. After learning more about it, he decided to give it a try. In 2018, Chris visited an aquaponics farm in Colorado, and the Nelson Pade facilities in Wisconsin. He took a 3-day mastery class with Nelson Pade, who is one of the premier companies in the aquaponics business. The farm consists of a series of tanks and plant beds where greens are grown on water instead of soil. Aqua Archer Farms have a “Family Plus System” consisting of four 100-gallon tanks with fish, and two 55-gallon clarifying tanks. Ammonia comes from fish urine, but the fish solid waste does not come anywhere near the food production. The ammonia that is produced by the fish is broken down organically by bacteria, similar to how it does in soil, producing nitrate that is beneficial to the plants. From the fish tanks, water goes into a degassing tank. Water is then put into beds where greens are floating on raft beds. Their roots go directly into the water. They use tilapia, which are considered a highly invasive species by Iowa Department of Natural Resources. The farm is required to have a DNR permit, an annual aquaculture permit, and the facilities are inspected by DNR to ensure they are following all environmental regulations. Although the fish are edible, selling them would require another expensive permit so they do not sell the fish. The fish are all males, which reduces the chance of unchecked population growth. They arrive as 1-5 gram fingerlings. As they grow, the size of the food pellets they eat also grows. Nelson Pade has their own meal formula, which does not include any bloodmeal. The fish are fed 3-5 times per day depending on their size. Because tilapia like to jump and can easily jump out of the tanks, the tanks are covered with nets. The fish live about 7 months. A general rule is to have 1 pound of fish per 2-3 gallons of water. A ¼ horsepower pump is all that’s needed to recirculate water through the system, in addition to using gravity as much as possible. It is an enclosed loop system which conserves water and improves efficiency. The plants take 30 to 55 days to grow to a harvestable size. They require temperatures between 65-85 degree F to thrive. Fans are needed to help circulate air. Grow lights are used in the greenhouse to help increase the light spectrum for the plants’ growth cycles, and generate small amount of heat. A “purge tank” system is used when they are harvesting the fish at the grow out stage of 1.5-2 pounds. They are taken from the 100 gallon tank once at weight and are not fed, to clean out their system. Salt is added as a calming agent and to help clean out the fish from any remaining waste, to produce a cleaner meat and taste when harvested. They add DTPA Iron, magnesium and calcium to the water. The iron is not readily available for the plants in this form of iron so they add the calcium and magnesium for the iron to attach to so the plants can uptake the nutrients. They have several biosecurity measures in place to reduce the risk of contamination and pests. They do weekly chemical testing of the water to make sure pH, nitrite, dissolved oxygen, and other qualities are adequate. Tanks are cleaned monthly (or as needed) depending on the fish stocking density. The Archers do not use any pesticides or other chemicals. Archer Aqua farms started growing produce about a year ago. To harvest the greens, they lift up the floating beds and snip off the roots. They are currently selling 9 types of greens, and plan to add berries and tomatoes in the future. Customers often comment on the great flavor of their greens compared to store-bought counterparts. They are planning to start producing Microgreens in the next month or so, using a ZipGrow Microgreens Station. The Archers are currently participating in Upstart University, where they’re learning more tools and tips of the trade.

You can find Archer Aqua Farm’s greens at the Blair Farmers Market in the summer, and at S&S Pumping in Blair in the off-season of the farmers market on Saturday mornings. One Farm Market in Logan also regularly sells them. They have at times sold to the Pink Poodle in Crescent. They will have anywhere from 70-90 heads of greens available each week. You can also contact them through their Facebook page to place an order. For a small fee, you can get a tour of their facilities. Flavor Country Farms, located in the Loess Hills near Honey Creek, is a small farm specializing in mushrooms and microgreens. They started at the current site in September 2018, but owner Kevin Novak had been growing in his Omaha basement before the move. Prior to that, Kevin spent several years in the restaurant industry in Chicago before returning to his hometown. While studying at Metro Community College, he became interested in fungi and tried growing mushrooms for the first time. Kevin is primarily self-taught, though he did attend a two-day training with world-renowned fungi expert Paul Stamets. Most of his expertise comes from years of experience and experimentation to figure out what works and what doesn’t. In January 2022, fire destroyed a building that was primarily being used for storage. The structure is currently being rebuilt as a packing house. Once completed, it will increase their capacity for production and storage. They plan to incorporate more value-added products like lion’s mane jerky, powder & capsules, and more. Flavor Country is a “chef-inspired” farm – Kevin asks the restaurant chefs what they want and caters to their needs. They currently sell to 40-50 markets per week, totaling about 700 pounds of product. The mushrooms grown by Flavor Country are called primary decomposers, and commonly are found in the wild growing on trees. The “big 4” – lion’s mane, oyster, chestnut & black pearl—are most popular for restaurants. Each variety has their own unique flavor and preferred recipes. Lion’s mane crab cakes, for example, are popular with many chefs. Oyster mushrooms grow the quickest are the least likely to be contaminated as they have the most aggressive mycelium to fight against contamination. Oysters are a great mushroom for an entry-level or hobbyist grower. Used mushrooms blocks are used to create mushroom compost for their vegetables. The mushroom process starts with clones or spores, then agar or liquid culture. From there is Generation 1 spawn, followed by Gen 2 and Gen 3. Next, it goes into a fruiting substrate, into incubation, then the grow room, and finally packing. The fuiting chamber requires very specific temperature, humidity, CO levels, and fresh air. An intricate geoair thermal battery was built into the ground beneath the grow room to help regulate the environmental conditions for optimal mushroom growth. October to March seems to be the best time to grow mushrooms, as they are not fans of the heat. Bugs like fungus gnats are more likely to cause problems in warmer weather. Besides mushrooms, Flavor Country’s microgreens are popular with restaurants. They currently sell 30 varieties of microgreens, but Kevin has developed at least 50 varieties over the years. They also grow garlic and several types of herbs. Squash blossoms are a popular seasonal treat that restaurants enjoy. For a while in the spring they even sell locally-harvested morel mushrooms. Flavor Country Farms' mushrooms, microgreens, garlic, and herbs can be found at numerous restaurants in the Omaha metro, as well as 712 in Council Bluffs and Pink Poodle in Crescent. In addition to restaurants (their primary customer), several Omaha grocery stores carry their products, including: Hy-Vees at 90th & Center, 180th & Pacific, and 96th & Q in Omaha; Exist Green in Dundee; and Berreras Farms at 194th & F. Additionally, you can find their products at Berreras Farms’ CSA, Iowana Farms’ CSA, and No More Empty Pots. They sometimes have a farm stand at the Casey’s in Crescent on Friday evenings.

They are also considering some on-farm events and are hosting a PFI Field Day this fall, so stay tuned! Follow Flavor Country Farms on Facebook, Instagram, and their website. Following gravel roads southeast of Clarinda, nearing the Iowa-Missouri border, I arrived at Garden of Paradise. Stepping out of my car, I understood why Shad Swanson chose Garden of Paradise as his business name. On this beautiful blue-sky afternoon our surroundings were quiet except for the occasional bird song and the croaking of frogs nearby. An old rundown one room schoolhouse sits within eye shot, a relic reminder of Iowa’s thriving rural past. What Shad does on his acreage is reminiscent of Iowa’s rural past, too and my idea of an Iowa paradise. Not all that long ago many Iowans, tasked with feeding themselves, grew large gardens outside their back doors. They may have gifted, bartered, or sold some of their bounty with their friends and neighbors. Shad is a market farmer, selling his produce at several small-town farmers markets in southwest Iowa.

The warm season crops are not planted out yet. They are still warm in their winter growing space. Shad starts his yearly garden routine long before the ground outside warms enough to plant. Many of the crops begin as seeds in his basement, which he refers to as his “greenhouse”. His basement is full of various peppers, Shad’s favorite garden plant, and tomatoes, and herbs. Everything is getting big and eager to go outside for the season. The basement does feel like a greenhouse. Shad grew up on a farm, just outside of Essex. His family grew a vegetable garden, and he participated in 4-H. His love of growing produce matured when he lived in Des Moines, growing produce to give to friends and selling some to restaurants. I asked Shad what made him return to rural Iowa and choose produce farming for his profession. He did not hesitate with his reply, “Iowa needs to diversify”. We agreed that diversity in both plant species and economic opportunities would be beneficial for rural Iowa. Shad remarked about the solitude and peace in his big back yard. You can’t get that in an urban setting. One day, Shad hopes to expand his growing operation, but for right now it is the perfect size for one man to maintain by hand. He is gaining invaluable knowledge, trialing varieties to determine what will work best for his expansion. His excitement about what he does shows. Besides the already mentioned produce, Shad grows various culinary and tea herbs, like lemon balm, sage, parsley, basil, and oregano. He sells jars of freshly dried and powdered herbs and peppers. Houseplants and cactus are also staples at his market table. Garden of Paradise can be found, among other area vendors, this Saturday, May 6th at 9am in Priest Park in Shenandoah for the Plant Sale and Market hosted by Sycamore Ridge Small Farm. Garden of Paradise can also be found at the Clarinda, Red Oak and Shenandoah Farmers Markets beginning in mid-May. Shad also plans to attend the new monthly Essex Market beginning Saturday June 10th, and other various markets that occur throughout southwest Iowa. Follow Garden of Paradise on Facebook for farm and market updates.

Duncans Poultry started in 1987 when Matt Duncan was 13 and his brother Wade was 17. Matt had experience working at a feed store in Beebeetown. They tried raising chicks and had them processed at a facility in Nebraska, but did not think the processor did the best job. They then processed some of their grandparent's birds, and started doing more processing from there. Early on, processing was completed in a small calf shed, which was quickly outgrown. Their primary customers early on were farmers. Many customers at first preferred only slaughtering and defeathering, and would do the butchering on their own. Eventually Duncans began selling chicks and feed, and doing more butchering. In the 1990s, a boom in acreage development significantly increased demand for chickens. Many people moved out to the country and wanted small flocks of a few birds to a few dozen birds. This demand increased even further in 2020 with the COVID-19 pandemic. Duncans thought it might be a temporary fad, but interest has yet to wane three years later. Their processing is custom exempt, which means poultry processed here cannot be sold to restaurants, grocery stores, or other commercial. Producers can “pre-sell” birds, meaning producers must pick up their own birds after processing. In 2020 they finished a new processing facility that can be state or federally inspected. So far, however, most of their poultry processing is still done in the older facilities. The new facility is primarily being used for deer processing, though they plan to use the state-inspected facilities more in the future. The ‘official’ building brings additional regulations and requirements, including a state or federal inspector on site during inspections. This takes longer and producers need to pick up their birds the following day, versus the same day with custom-exempt processing. The benefits of the state-inspected processing include meat could be sold at commercial outlets across Iowa. If they chose to use a federal USDA inspector, meat could also be sold across state lines to Nebraska and other states through the CIS program. With the custom-exempt processing, Duncans can get through about 100 birds per hour. Each year they process 30,000 birds or more. They raise about 1,000 of their own birds each year, and their customers come from across Iowa, Nebraska, and other nearby states. In addition to processing, Duncans sell a lot of chicks, feed, vegetable seeds, honey, and other farm supplies. Their nest boxes are becoming increasingly popular. They also have a level of knowledge of these products that most big-box store staff do not. If you’re interested in raising poultry, contact Duncans! Even if you’re not, check out their farm store and museum with historic artifacts relating to poultry and farming. Store hours are 8am-2pm Monday thru Friday and 8am-Noon Saturdays. Check out their website and Facebook page to learn more.

3 Bee Farms started with beekeeping in 1993, selling honey at farmers markets. Over time, they have expanded to a wide variety of vegetables and more. They currently have about 10 acres of crop production, which include Asparagus to Zucchini and everything in between. In addition to fresh produce, they sell live plants such as succulents, bedding plants, and flower & vegetable starts. They also have jams, jellies, and dressings made with some of their products. They may be known best for their hydroponic tomatoes. Their largest crops in terms of acres are pumpkins and gourds, including many unique varieties of colors and textures. They have more than 10 varieties of apples in the orchard. Kohlrabi and golden beets are some of their more popular crops, as well as onions, rhubarb, asparagus, and zuchinni. They even have a small herb garden. You can find a full listing of all 3 Bee products at https://www.3beefarms.com/products

In the fall, the farm is popular for family-friendly activities like a corn maze, pumpkin patch, outdoor games, and food. Their honey-glazed snack mix is especially popular, and they have apple pies in the fall. These activities are from the Tuesday after Labor Day through Halloween. Each year they try to add new activities and amenities. Customers come from across southwest Iowa, Nebraska, and beyond. You can find 3 Bee Farms products at several farmers markets in southwest Iowa: Monday in Creston, Tuesday in Anita and Treynor, Wednesday in Avoca, and Thursday & Saturday in Council Bluffs. The greenhouse is open 10-5 Monday-Saturday and 1-5 Sunday in April and May. Details can be found at https://www.3beefarms.com/events |

Archives

June 2024

Categories

All

|

Address712 South Highway Street

P.O. Box 189 Oakland, IA 51560 |

ContactPhone: 712-482-3029

General inquiries: [email protected] Visit our Staff Page for email addresses and office hours. |

RSS Feed

RSS Feed